History and Development of Telefunken Steel Tubes

One of the most sought after tubes today is the Telefunken VF14 steel tube. Built from 1946 to 1957 in three production runs totaling about 27500 total pieces, it was originally developed as an impedance converter for the Telefunken distributed U47 microphone. Since its introduction, the VF14 has never really fallen out of favor, so starting in the early 70s it proved quite difficult to find good replacement tubes. From about 2000, the VF14 started to climb in price and a good working specimen sells these days in the price range of $2000 to $3000. For most other tubes made there are several replacement options, but due to its high filament voltage and its odd socket it is impossible to find a direct replacement. One of the challenges is that very little information is available for the VF14, but rumors and shady stories are found all over the internet. In nearly all cases these stories are far away form reality. Even Neumann, the manufacturer of the U47, has very little on information on the VF14 other than they used it in their mic. Due to its specialty use it was not mentioned in too many technical books, if at all.

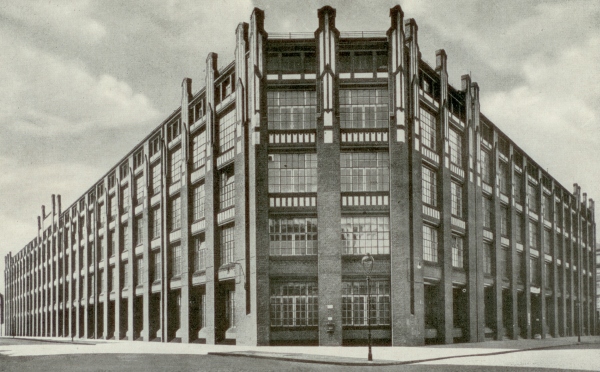

The story of the VF14 starts with the introduction of the Telefunken "Stahlroehre" which means steel tube and coincides at the time that Telefunken started to become a manufacturing company. Up to 1939, Telefunken was purely a distribution company that sold items produced by either of its parent companies, AEG and Siemens, as well as products made by third-party manufacturers. That changed on July 1, 1939, when AEG and Siemens agreed to consolidate all their vacuum tube production into one entity. Up to that date all of the Telefunken labeled tubes were either made at the Osram light-bulb factory "Werk A" located in Berlin, the vacuum tube factories of AEG in Berlin Oberschoenweide or the Siemens Wernerwerk in Muenchen. Because of the fact that the Osram (also a joint venture of AEG and Siemens) plant "A" was already Germany's leading vacuum tube manufacturing plant, all other production machinery from the other factories that were involved with vacuum or radio tube production were relocated to "Werk A" and the manufacturing plant started to operate as "Telefunken Gesellschaft Roehrenwerk Berlin"

The fast growing German radio industry of the 1930's created challenges for the tube manufacturers to meet the demand for the radio customers. All manufacturers were sharing the patents of the Lieben tube, and production was spaced out in several factories over Germany. As a result, they could not supply enough tubes for the German market. Another problem was that development was also done in the Research Institutes that were located in entirely different cities than where the factories were located. Due to their inability to meet demand, international competition was trying to gain market share in Germany and to keep up with the development on the world wide market, new inventions and fast advancements on the production side were required to maintain the lead position in the German electronic industry.

The goal of the two leading German electronic companies was to create a central entity that would house the development for material science, machinery research and production, as well as to coordinate marketing and distribution. In addition to consolidation, the main goal was to develop an entirely new way of building vacuum tubes. Up to the mid 1930's, the vacuum tubes were nothing more than a modified light bulb: a filament wire suspended in a glass envelop with a metal plate and grid. Since the beginning of the industrial production of vacuum tubes in the mid 1910's, not much had changed in how tubes were built. The basic idea was to introduce new production materials that could enable tubes to be built faster, improve the technical specifications as well as prolong the lifetime of the tubes. The new production methods would also improve the appearance of the old coke bottle style tube and the old glass stem bottoms with their parallel running input wires would be replaced by the pressed glass plate foot that was able to reach higher frequencies than previously capable.

In addition to the traditional "new is better" marketing approach which provided a need for better technology, there was also a need for finding an economic solution to build tubes more quickly. AEG and Siemens moved into a radical new direction. Their answer was a small steel container made from a newly developed vacuum grade steel developed by Hoesch. Steel by nature is not the best material for vacuum work due to its propensity of outgassing and thus losing its vacuum. But because of its lower price than nickel it was the ideal solution from a cost perspective. AEG and Siemens were trading the life span of the vacuum tube for lower production costs. However, with the newly developed alloy by Hoesch, most of the long-time outgasing problems that come with steel were mitigate and for the first time in history an all steel tube envelope was propagated for the vacuum tube of the future.

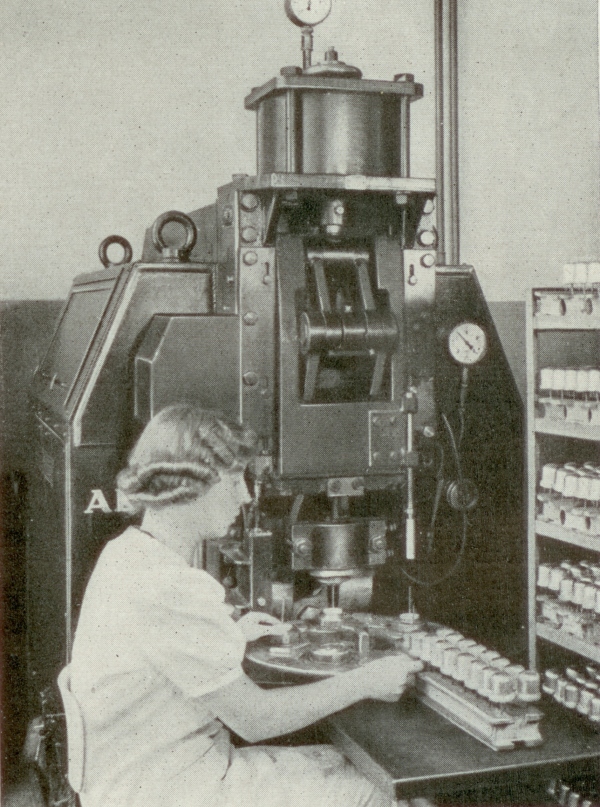

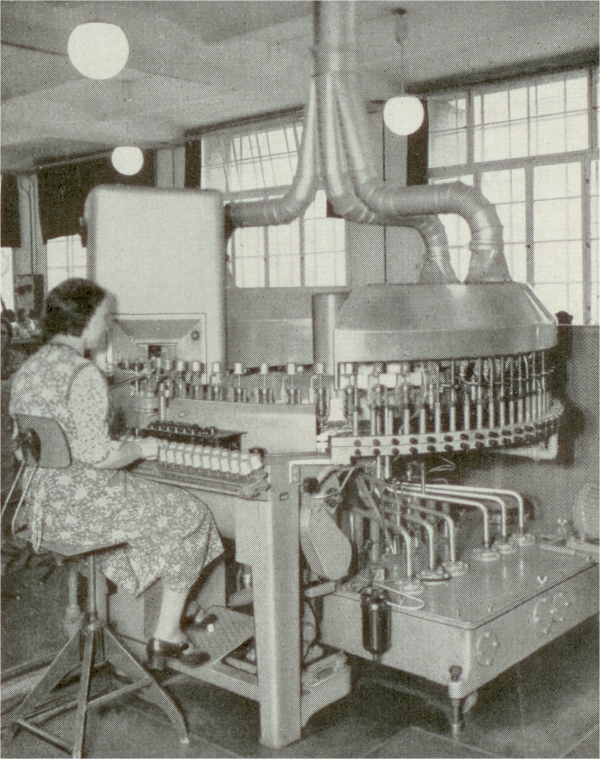

Entirely new machines needed to be developed to achieve the task of making all steel vacuum tubes. The vacuum sealing welder in its day was a technological marvel. About 3 different versions were built but all were capable of supplying 170000A welding current at 70V AC- enough to power two city blocks today! The lead-in plate to connect the electrodes was made from a specialty steel alloy to which Fernico eyelets were brazed. Each eyelet was filed with a specialty glass with a lead-in Fernico wire. Every machine was high tech for its time and each was developed and built by Telefunken and AEG in house.

For the first time, sub assemblies for the steel tube could be build on automated machines, not just the envelop or the lead-in plate. The support parts were constructed of vacuum grade steel instead of glass or ceramic pieces requiring less skilled workers. With the standard glass radio tube of the day, 23 specially trained people could assemble 100 tubes an hour, whereas with the steel tube machinery, 5 partially trained workers were only needed to complete the same number of tubes in that time. The only hand labor required was still the electron cage, which was still fully in the hands of female workers.

The future of the newly introduced steel tubes was not too rosy or benign. With the outbreak of WWII, within a few months, what was once the consumer oriented steel tube production became the backbone of the Nazi electronic war machine. About 80% of all wartime electronics was built around the steel tube. The most famous of the so called Wunderwaffen was the Aggregate 4 better known as the V2 rocket. It used four EF14 steel tubes in its guidance system and historically the steel tube became the first vacuum tube that proved itself space worthy. During the war Telefunken expanded the production of the steel tubes to all captured tube factories in the occupied countries. Telefunken also expanded the production within Germany and set up two more tube factories; one in Erfurt and one in Neuhaus (both of those became RFT tube factories after the war). It is not 100% certain how many steel tubes were made during the war, but starting after 1940, several companies started to manufacture glass versions of the steel tubes to meet the demands of the war.

Due to the massive Allied bombing of Germany at the closing of WWII, nearly all Telefunken tube factories were all or partially destroyed including much of the documenation for producing these tubes. By the end of the war only the make shift tube factory in Ulm (relocated during the war from Lotz, Poland) was still operational, but it did not have steel tube production capabilities.

More to follow soon...

Also Read: