UM57... Meet the UM351 Transformer

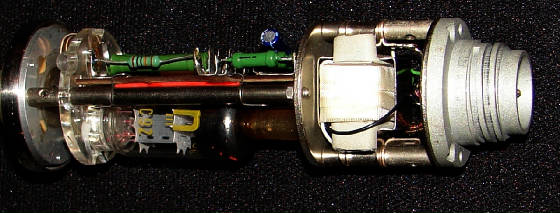

The story of the UM351 starts at the beginning of our company’s history when we first launched the TAB Funkenwerk line in the late 1990’s. My good friend Dirk Groll, one of Europe’s best music journalists, had helped me round up all that was left of the historic TAB company. One day he asked me for my technical opinion about Neumann Gefell mics made during the time when the GDR was a separate country. Over the years, Dirk had bought a large number of GDR made Gefell mics (CMV563, UM57) and while all of them passed signal, none of them were in suitable condition for use in a recording studio. After he weeded out all of the bad capsules, power supplies, etc., what he had left were just a few buffer amplifiers that sounded OK but none were in the same battle class as the historic Neumann’s made in Berlin.

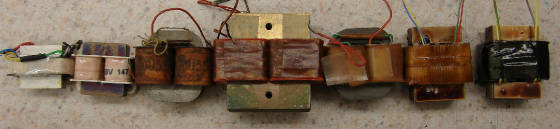

My suggestion was to check all of the buffer amplifiers with one reference tube and measure the static value to see how close they were to each other and the original specs. The test showed that the amplifiers were all over the map. At that point, Dirk asked me if he could send me all of the transformers that he found that were broken or just sounded bad for rewinding. He also sent one that he thought sounded acceptable as a reference copy. When the package from Germany arrived at my shop in Seattle, I found what you would expect from GDR era made transformers- inconsistent materials. The challenge for Gefell during the GDR era was that acquiring the proper raw materials was difficult and their quality fluctuated drastically. Since production could not cease, they used whatever materials were available when they needed them in order to meet their monthly quotas. From the 10 transformers that Dirk initially sent to me, there were three different ratios and eight different types of alloy used for the lamination. Rewinding them was not going to fix the problem and even Dirk’s reference transformer was of a very low sound quality.

At the 2000 AES Show held in Los Angeles, I had a conversation with Mr. Kuehnast who was at that time the General Manager of Gefell. He told me that during the GDR days, Gefell had to make the lamination in house. They stamped it, heat treated it and they literally had to cut the corners of the lamination to conserve the nickel based alloy that was quite difficult to get a hold of. Under the circumstances, they did quite a good job to meet the government production quotas (according to Mr. Kuehnast, 1.6 metric tons a month!). Over the years I have encountered Gefell transformers with lamination that consisted of everything from plain old dynamo grade alloy to sintered Nickel dust cores. It was because of this wide varying lamination that the winding ratios also changed in an attempt to make up for the lower grade materials.

Upgrading the mics with a Neumann (Berlin) style transformer along the lines of a BV8 or BV11 was not an option due to the space limitations of the mic body tubes. I tried a KM54 style transformer which was also not optimal as there were headroom issues when the mics were used during close up micing. After a few days of debating and trying to find an American style lamination to fit the situation, I finally gave up and started to make tooling in the style of the historic Gefell GN551 lamination. My goal was to come up with a lamination that would be as close to the original Gefell lamination but with consistent material properties that would capture the spirit of Gefell's original intentions.

During my evaluation of the various Gefell transformers I found them to have winding ratios anywhere from 6:1 to 14:1. I wound a few prototypes with different ratios and winding techniques and tested them all. Eventually, I settled on a secondary over primary with a chamber style winding pattern at a 6:1 ratio that seemed to work best with the EC92 tube found in both the Neumann Gefell CMV563 and UM57.

The last decision to make on the transformer, and perhaps the most controversial, was whether or not to incorporate a faradaic shield. There has been an ongoing technical debate as to whether a shield is needed within the transformer to reduce external noise (RF or EMF). All of the Neumann Gefell mics incorporated a faradaic shield in their transformers. However other classic tube mics used transformers without a faradaic shield: Neumann U47 and M49, AKG C12 and Telefunken Ela M 250/251. When used in a studio that has been properly wired none of these mics exhibit any noise issues due to a missing faradaic shield.

Unfortunately, any shielding added into a transformer disturbs the magnetic flow in the transformer. Having done experiments with building the same transformers with and without faradaic shields, the shielded transformers have a loss of high end frequency response as well as a loss of clarity and resolution of signal. I decided that the potential noise cancelling benefits of the faradaic shield were minimal while the negative impact on sound quality was high and made the decision to not incorporate a faradaic shield in the UM351.

As a side note, when Microtech Gefell (the follow up company of RFT Gefell) chose the UM351 transformer for their 75th anniversary mic, the UM75, they ask us if we could make the UM351 with a faradaic shield. Their standing policy is that all of their mics must use a faradaic shield in their transformer. After several weeks of discussion where I pointed out the benefits for not using a shield, they finally agreed to use the UM351 exactly as I designed it. Talking with Mr. Rowehl, the former Microtech Gefell sales manager, with 75 UM75 mics delivered there were no complaints of noise but lots of compliments on the brilliant tone that the mic produces.

With the lamination selected, faradaic shield decision resolved and the winding ratio set, I made one transformer using one of the Gefell cores that seemed to be made of a Nickel alloy along with a control sample that was made with the lamination that I had made. The samples were sent back to Dirk in Germany and after several tests he decided that the control sample did the most justice for the Gefell-made PVC capsule. After several additional tests in my shop, I incorporated Dirk’s suggestions and the AMI UM351 replacement transformer was born. I do not know if we successfully captured the original Gefell spirit, but when you couple the UM351 transformer with a rebuilt Gefell buffer amp (new precision resistors and capacitors) the “People Owned” Neumann certainly competes with its cousins that were manufactured in Berlin. Once the design was finalized, I sent Dirk a big box of the UM351’s and he started to refurbish all of the Gefell mics in his collection. Any capsule repairs were done by Mr. Thiersch.

It is hard to unequivocally state how a microphone should sound that was made over 50 years ago with such a wide variety of parts and materials used in their construction. However, the end result is very pleasing and makes a good quality mic. The mics are less well known here in the US as very few ever came over during the cold war. Most people who know of these GDR Gefell mics were due to seeing film of Louis Armstrong performing at Lucerna Hall in Prague, 1965. The footage of him using a UM57 generated interest in the mic here in the US however, it was nearly impossible to get them into the US. There are stories of folks smuggling UM57’s through Cuba into the US but the interest was minimal due to the inconsistent quality of sound from the mics. Now there are options to refurbish these wonderful microphones and make them an integral part of one’s recording studio.

Schematics for Mic Rebuilds using the AMI UM351:

Also Read: