The U73: Variable Transconductance Compressor

The first wireless transmissions were of wireless telegraphs. With the telegraph apparatus essentially being a binary sound source (on or off) it was quite simple to use the early broadcast equipment to dial in the appropriate volume level to appropriately hear the communication being sent. Even during the earliest voice transmissions, given that they were either government or military transmissions to other government or military installations, the expectation for sound quality was quite simple; if you can understand the message correctly, the sound quality is good enough.

Once radio broadcasts began to be used for commercial purposes, the expectations of sound quality and needs for audio broadcasts began to change. Listeners did not want to listen to radio broadcasts that jumped in various volume levels across a program as they didn’t want to have to sit next to the radio and “ride” the volume knob. Radios were also an expensive proposition at that time and new owners would not be pleased to have their speaker blown out due to these jumps in volume. A piece of equipment needed to be created that could smooth out these transmissions and protect the listeners on the other end.

The world’s first dynamic compressor was the Telefunken U3. Designed in the early 1930’s it saw its first use at the 1936 Olympics. Built on a circuit that was designed to protect against frequency modulation distortion due to sudden input overloads to the system, it was used on the public address system at the Olympics. Not many of these units were made and it is doubtful that many (if any) have survived.

The U13 was the next generation of audio compressor. Introduced in the 1940's, it was developed based on the same components and technology as the V72's predecessor and was the first diode bridge compressor ever designed and made. This unit is literally the grandfather of almost every modern non-tube compressor.

In 1953 Rhode und Schwarz developed the U23 and it was commercially introduced in late 1954. Used as an overload protection device at radio stations, this unit was a technological achievement in studio equipment for the 1950s. Using 3 EF804S, 2 EAF 42, 1 EB 41, and 1 ECC 40 tube, this unit is very similar to a Fairchild 660 in both design and sound. If a signal came into the unit at +6 dB (or it could be set for +12 dB) the unit would kick in and reduce every 10 dB to 1.5 dB.

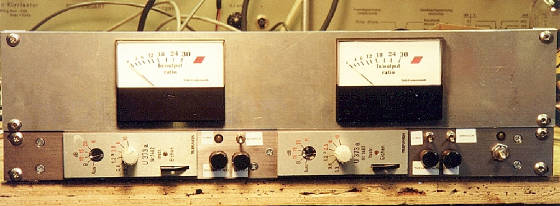

While the U23 was a quality compressor, it still did not conform to the high standards of the IRT. Looking for a solution that was fully capable of handling the full frequency response of FM radio broadcasts, the IRT started development on the U73. Working again with the NWDR in Hamburg, the U73 was developed over a 3 year period. Built into a double Danner cassette module chassis like the V76, the U73 shared significant circuit features with the V76 and used roughly 50% of the same components as the V76. The U73 is a three stage push/push variable mu design with a theoretical compression ratio of 100 to 1. The unit was yet another landmark design by Telefunken/AEG as it was the fastest tube compressor ever built due to its forward triggered side chain.

Once the design was finalized, it was licensed to the historic TAB corporation of West Germany who produced it for almost 30 years until finally discontinuing the model in 1980. This was the last tube compressor made in the Telefunken/IRT gray series. Due to its high price and fixed set-up, the U73 only found its way outside Germany in one specific application; as a final mastering compressor for disc cutting laths, mostly in conjunction with an automatic release trigger; the Varicom. Nearly every record recorded and cut in Europe from 1960 to 1980 was mastered through a stereo pair of U73’s.

Variations of the U73 Compressor

TAB ended up making 5 different versions of the U73 compressor for Telefunken. The U73, U73a, U73b, U73bt, and the U73ts. All of the units shared similar design aspects but each had it's own characteristics based on the build or the final intended usage.

- U73: The standard U73 unit was designed for talk radio use and does not come equipped with any controls for overall compression levels or the ability to adjust the attack and release times for the unit.

- U73a: Because the units are forward triggered, the term "compression ratio" is not completely accurate when discussing the control of compression with these units. The U73a allowed you to set the "compression stroke" but since it is forward triggered the ratio was constantly changing pending the dynamic signal that came before it making it a non-linear compressor. Most of these units used EF83 tubes and are very rare.

- U73b: This is the unit that is most widely known and was most commonly used for producing audio recordings. Designed for the studio, the U73b not only allows one to change the level of compression but also has a control on the outside to change the Release time and a control on the inside to change the Attack time as well. These units used E99F tubes and therefore had a slightly different sound and schematic from the U73a.

- U73bt: The U73bt came out after the U73b. The U73bt provided the same controls as the U73b but the amplifier utilized a mixture of tubes, nuvistor tubes and transistors to achieve its sound.

- U73ts: The U73ts was the first Telefunken compressor to use only transistors. The unit is very similar to the later U373b made by TAB except that it came in the U73 sized housing with its own power supply.

- U83: This was a limiter like the U73 that came with a different preset threshold and no ability to change them like the U73.

TAB in conjunction with EMI (a subsidiary of Carl Lindström AG) made several mini versions of the U73 that could be inserted into the effect loop of the V76S, the studio version of the V76. This mini U73 does not work for the V76/80 or V76/120 versions.

Other U Series Compressors

With the arrival of transistors, Telefunken and its manufacturing partners embraced transistors into their designs in order to create compressor modules that could take up less space and generate less heat.

In 1960, Siemens introduced the U273 the world’s first solid state compressor. There is a dispute over whether or not Neve based their 2254 compressor on this module. There are striking similarities to the schematics but one of the main differences is that the Neve uses Marinair transformers while the U273 used Haufe. The Siemens U273 is one of the best sounding transistor compressors ever made.

In 1963 TAB introduced the U373, an upgrade version of the diode bridge design, made with transistors that took the edge off the distortion. TAB built several different versions; the U373a/b/c, the U273a/b version for Siemens and the U373TS version of Telefunken. The U373 group is the only non-VCA compressor that works similar to a remote cut-off tube compressor.

Neumann, Filtek (BFE/Siemens) made several spin-offs off the U373, some with DBX or other VCA chips. These are reasonable units but not nearly as good sounding as the historic TAB U73 or U373 types.

There are several WSW (Siemens in Austria) solid state compressors based on the early U273 design that sound too good to be transistor based…

Also Read: